Background of the QFD toolThe Quality Function Deployment (QFD) process is a structured approach to defining customer requirements and needs, and then translating them into specific plans and specifications to produce products to meet the customer needs. The customer requirements and needs are sometimes referred to as the “voice of the customer”. This is the term used to describe the stated and unstated customer requirements and needs.

The QFD tool

The QFD process is oriented toward involving a team of qualified and experienced individuals representing the various functional departments of a company that are involved in product development. This should include and not be limited to:

- Marketing

- Project Management

- Design Engineering

- Quality Assurance

- Manufacturing

- Manufacturing Engineering

- Test Engineering

- Finance

- Product Support

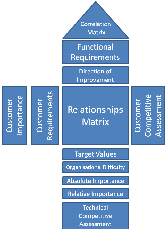

The House of Quality comprises rooms or steps to the QFD process. These are:

|

|

The QFD tool can be used where any goods, services or processes are being developed and is used extensively in the Automotive environment. Essentially the QFD process should be applied in the development of any products where, meeting the needs of the customer very well, is important. This could be in new product concepts or if the market is very competitive and a product advantage is needed.

This one day on-site QFD training course starts with an overview of the QFD tool and the QFD process.The intent of this and all our training courses is not to tell or show the trainees what to do but to impart the capability to perform the required tasks. There is no limit to the number of trainees but we strongly recommend no more than 5 individuals attend per course. We find that if there are any more than this the training becomes ineffective and wasteful.

This course is targeted at the product design engineers, the manufacturing engineers and the programme managers delivering new products. This training course is given in English. All our courses are designed to be informal and are based around a series of discussions and practical exercises. A QFD excel template is provided.

Another great training solution from Product Development Consultants

No comments:

Post a Comment